Product safety and quality control monitoring as well as compliance with legal regulations is one of the most important aspects of modern food business. The manufacturers face numerous challenges such as contamination, inadequate processes, and environmental concerns. As a biotechnology enabled company in the field of environmental protection, we provide tailored solutions for sustainability-focused production process testing Services. We strive to eliminate food safety concerns by integrating cutting-edge analytical procedures, environmental surveillance, and process management and monitoring techniques at every stage of food production including receiving raw materials and packaging the final product. Consequently, we help food manufacturers attain operational control, decrease waste materials, and comply with the international standards on sustainability through addressing the critical control points.

In the effort to meet the latest requirements on international food safety regulations and increasing environmental sustainability concerns, CD BioSciences has invested in advanced biotechnology and analytical instruments to meet the growing demand for Production Water Testing Services. We make certain that the water used in food manufacturing meets operational and regulatory standards of the industry.

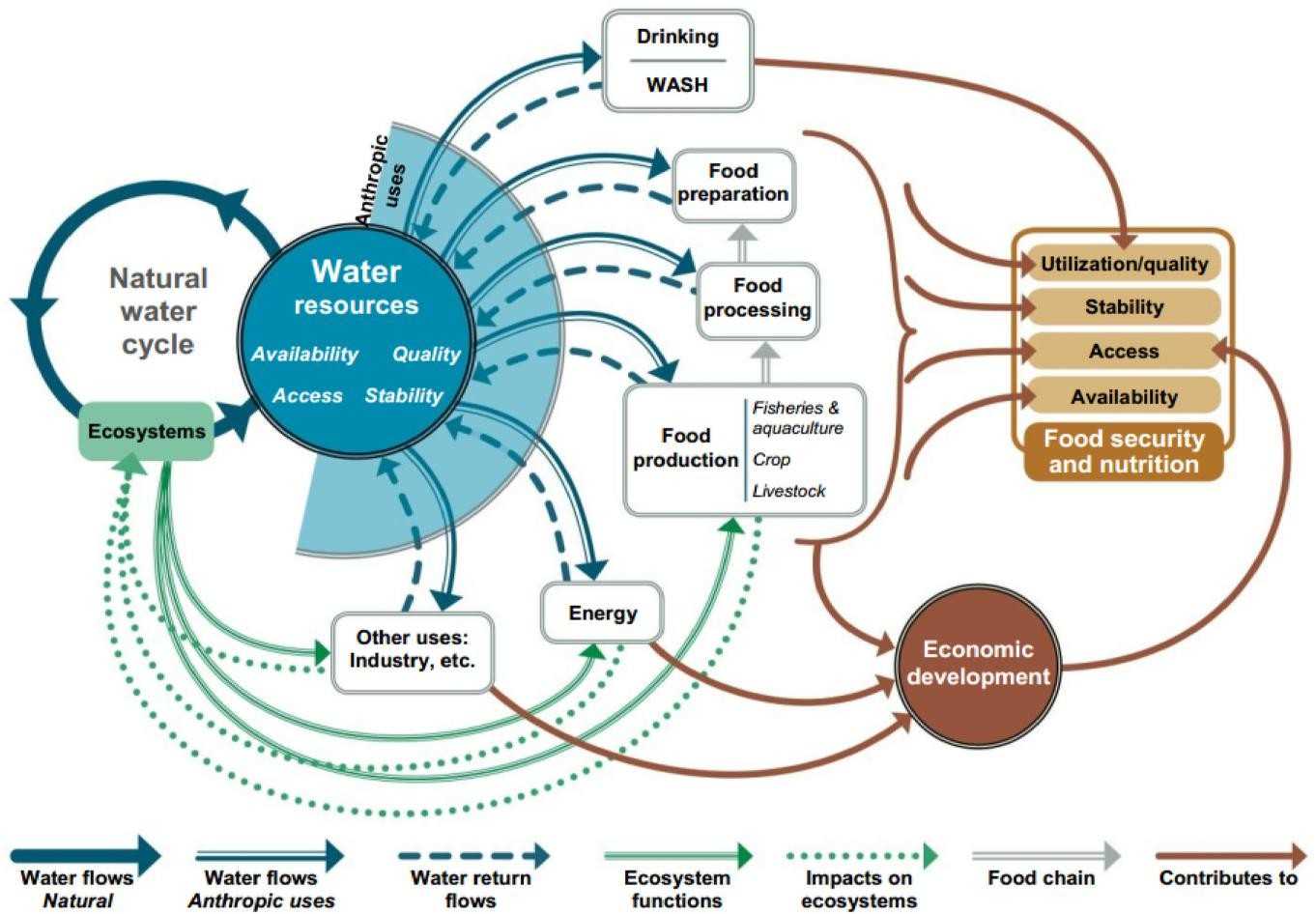

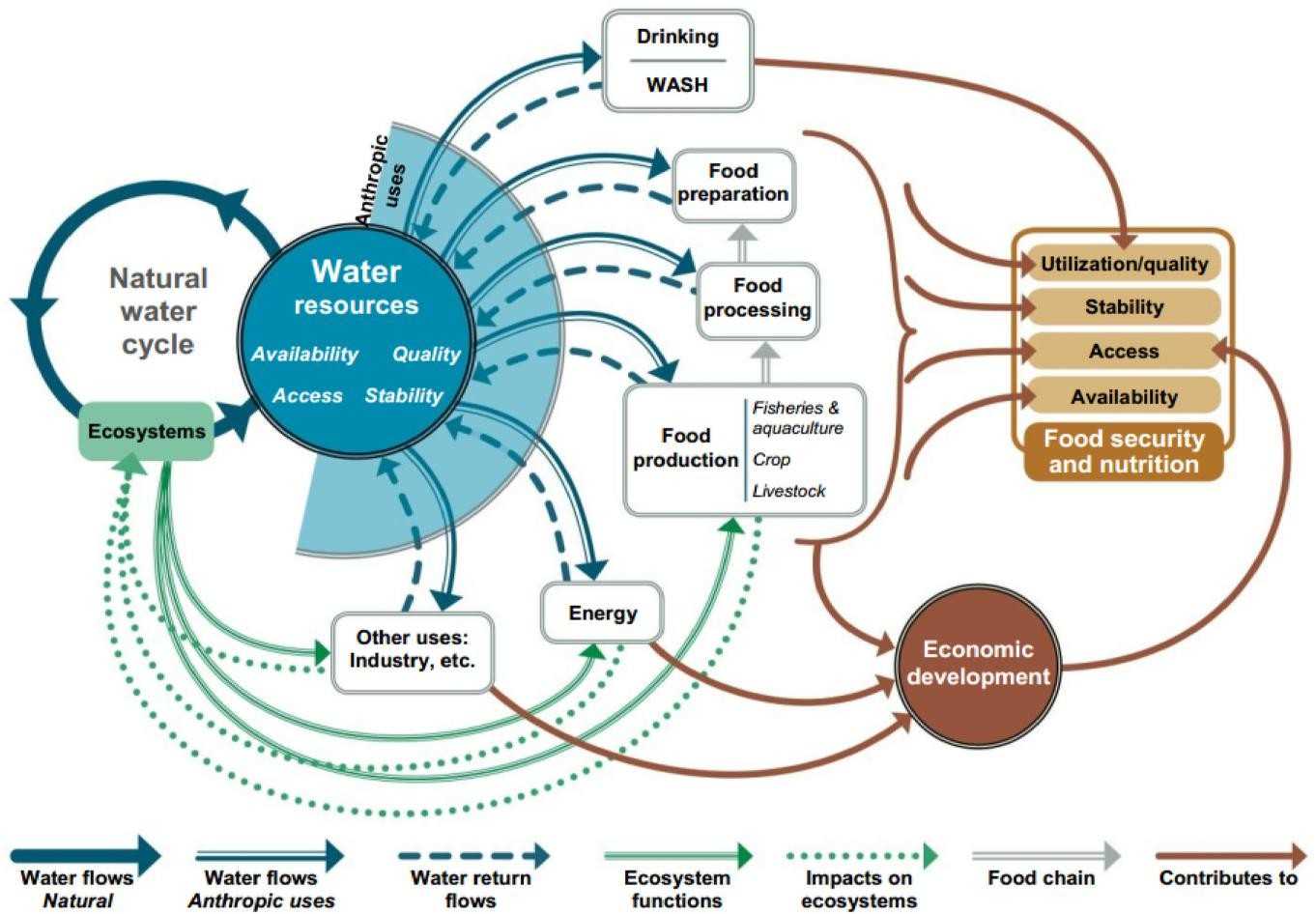

Fig 1. Water in transforming food systems (Claudia R., 2022)

Service Overview

Our company has developed a complete solution to analyze water quality for food and beverage companies. These are among the most important areas we work within:

- Microbiology: Bacterial detection and typing (e.g. E. coli, Legionella), viruses, fungi etc.

- Chemistry: Detection of heavy metals (e.g. Pb, As), pesticides, other organic, and disinfectant byproducts.

- Physical: Turbidity, pH, conductivity, hardness, and dissolved oxygen.

- Tailored Approaches: Testing procedures organized around the sector’s needs (infant formula and plant-protein meats for example).

Our procedures enable detection of threats from the billion parts-per-level (ppb) ensuring risk is identified and decontaminated as soon as possible.

Technical Principles

The tests are based upon the most advanced technologies:

- Molecular Biology Techniques

qPCR: Detection of pathogenic DNA or RNA at fast speeds like (Salmonella or Norovirus).

Next Generation Sequencing: Metagenomic profiling with an ability to find threat microbes that cannot be cultured.

- Spectroscopy and Chromatography Methods

ICP-MS: Hyper sensitive finding of heavy metals with a detection limit of 0.1 ppb.

GCAM: GAS chromatography with organic compounds (VOC) and pesticides.HPLAC: Estimation of antibiotics, hormones, and mycotoxins in food.

- Sensing Device Technology

Monitoring of pH, turbidity and chlorine in water using IOT sensors, enabling daily probing. Cloud servers are used to collect data for easy access anywhere.

Technology Characteristics

- Speed: Same-day news considering important information such as coliforms by means of ATP bioluminescence.

- Accuracy: verified true results from ISO/IEC 17025-accredited laboratories with proficiency tests conducted in other places.

- Comprehensiveness: Multi-Parameter panels cover >150 contaminants.

- Sustainability: 90% less then traditional cases has compared to methods avoiding use of solvent.

- Scalability: Designed for multinational companies while meeting the needs of small artisanal producers.

Environmental Benefits

- Water Conservation: Decreased consumption of fresh-water from 30 – 50% by a validated closed-loop system.

- Cost Saving: Reduced carbon footprint by more efficient energy using tested working methods.

- Regulatory Alignment: Assistance for UN SDG 6 (Clean Water and Sanitation) and ESG reporting.

Our Services

We offer a comprehensive suite of production water testing services, including:

- Routine Monitoring

Frequency: Daily/Weekly

Parameters: pH, chlorine, total dissolved solids (TDS), heterotropic plate count (HPC).

- Risk-Based Testing

Triggers: Seasonal changes and source water contamination alarms.

Focus: Pathogens, Endocrine disruptors and microplastics.

- Crisis Response

Outbreak Investigations: Conducted via root-cause analysis utilizing whole-genome sequencing.

Recalls: Supporting traceability to isolate contamination source.

Company Service Distinctiveness

- Expert Team: Scientists with deep expertise in raw material analysis

- Advanced Technology: Efficient and precise testing with state of the art equipment.

- Bio-Sustainability: All operations activities are eco-friendly.

- Tailored Solutions: Individualized testing to address all your requirements.

Contact Us

Water shortages alongside food safety challenges are some of the greatest threats today. This is precisely why CD BioSciences helps the food sector deliver operational resilience while acting responsibly for the environment. Our production water testing services utilize and reflect accuracy, technological advancement needed and a focus on the client enabling to preserve public health and the resources of the planet. Contact us to learn more information of how we can assist you.

How to Place an Order

Reference

- Claudia R., Mure A., et al. "The role of water in transforming food systems" Global Food Security 2022, 33:100639.

Our products and services are for research use only and cannot be used for any clinical purposes.

Production Water Testing

Production Water Testing Fig 1. Water in transforming food systems (Claudia R., 2022)

Fig 1. Water in transforming food systems (Claudia R., 2022)