Enzymatic Degumming

In the textile industry, degumming is a crucial process for removing sericin, a natural gum that coats silk fibers. Traditionally, this was achieved using harsh chemicals and soaps, which posed significant environmental challenges and could compromise the quality of the silk. Enzymatic degumming has emerged as a revolutionary alternative, providing a sustainable and efficient solution that minimizes environmental impact while enhancing silk properties.

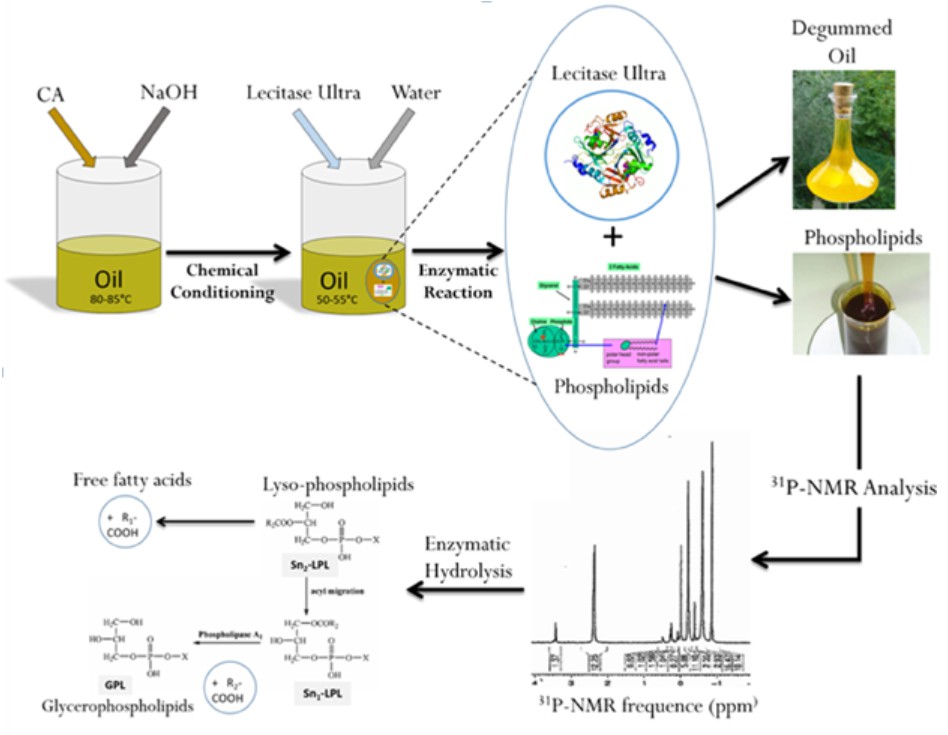

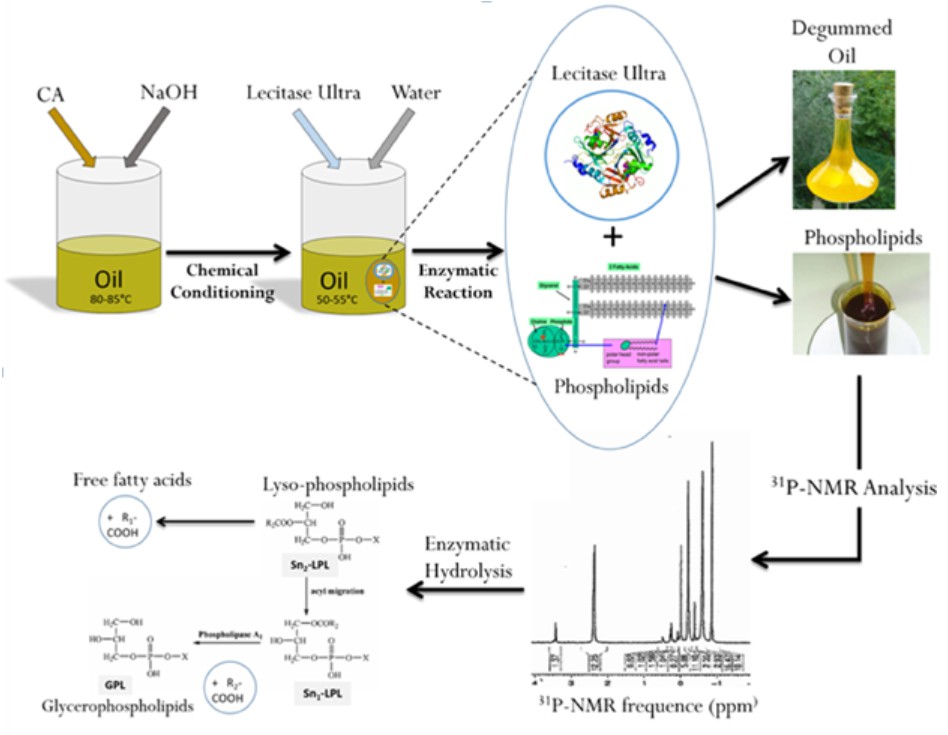

Fig 1. Enzymatic degumming (Klicia A., 2014)

Service Overview

CD BioSustainable is a leading bio-environmental company specializing in enzymatic degumming services for the textile industry. Our innovative approach utilizes specifically selected enzymes to gently and effectively remove sericin from silk fibers, resulting in superior quality silk with minimal environmental footprint.

Technological Principles

Enzymatic degumming harnesses the power of natural enzymes, specifically proteases, to break down the sericin protein. These enzymes catalyze the hydrolysis of peptide bonds within the sericin structure, effectively dissolving it without harming the delicate silk fibers. This process is carried out under controlled conditions of temperature, pH, and enzyme concentration to ensure optimal performance and fiber protection.

Technical Features

- Gentle on Silk: Our enzymatic degumming process is exceptionally gentle on silk fibers, preserving their natural strength, luster, and elasticity.

- Enhanced Silk Quality: By effectively removing sericin, our process improves the drape, softness, and dye uptake of the silk, resulting in higher quality fabrics.

- Reduced Water Consumption: Compared to traditional methods, enzymatic degumming significantly reduces water consumption, contributing to water conservation efforts.

- Lower Energy Requirements: The process operates at lower temperatures and requires less energy than conventional degumming, promoting energy efficiency.

- Minimized Waste: Enzymatic degumming generates less wastewater and reduces the reliance on harsh chemicals, minimizing environmental pollution.

Technical Classifications

- Bacterial Proteases: Derived from bacteria like Bacillus subtilis and Bacillus licheniformis.

- Fungal Proteases: Obtained from fungi such as Aspergillus oryzae and Aspergillus niger.

- Plant Proteases: Extracted from plants like papaya (papain) and pineapple (bromelain).

Application Areas

Enzymatic degumming services are applicable to a wide range of silk fabrics and textiles, including:

- Silk yarn and threads

- Woven silk fabrics

- Knitted silk fabrics

- Silk garments and apparel.

Environmental Benefits

- Reduced Water Pollution: Minimal wastewater generation and reduced reliance on harsh chemicals contribute to cleaner water streams.

- Energy Conservation: Lower energy requirements help reduce carbon emissions and promote energy efficiency.

- Sustainable Practices: Our enzymatic degumming process aligns with sustainable textile production practices, promoting a greener textile industry.

Our Services

At our bio-environmental company, we pride ourselves on providing cutting-edge enzymatic degumming services for the textile industry. Here's an overview of the services we offer:

- Ultrasound-Assisted Enzymatic Degumming: We utilize high-frequency ultrasonication pre-treatment to enhance fiber degumming efficiency.

- Optimized Enzymatic Degumming Process: Our process is designed to reduce the demand for sodium hydroxide (NaOH), thereby minimizing environmental impact and improving the sustainability of fiber processing.

- Partially Purified Enzyme Solution (PPES) Production: We co-produce PPES containing pectinase, cellulase, and xylanase through ultrasound-assisted fermentation of orange peels using Bacillus subtilis ABDR01, ensuring a sustainable and effective enzymatic solution.

- Chemical-Enzymatic Coupling: We offer a combined chemical and enzymatic degumming process that results in gum content of less than 3%, producing fibers with high tensile strength.

- Enzymatic Deep Degumming: This service increases yield by up to 1.5% while reducing phosphorus levels, converting non-hydratable phosphatides into fully hydrated lysolecithin during gum removal.

- PLA1 Enzyme Application: Our phospholipase A1 enzymes provide a robust, stable, and flexible process that reduces the need for hazardous chemicals, improving safety and sustainability.

- Enzymatic Water Degumming: For oils with high phospholipid content, we recommend enzymatic water degumming, which breaks down phospholipids into diacylglycerol (DAG) and a water-soluble, phosphate-bearing ester fragment, reducing gum content and oil loss.

- Acid Degumming: This process enables the separation of gums and impurities from selected animal fats through the intensive mixing of citric acid and water at controlled temperatures.

- Special Degumming: We also offer specialized degumming services tailored to specific customer needs and oil types.

Company Service Advantages

- Environmental Sustainability: Our enzymatic degumming processes are designed to be eco-friendly, reducing chemical waste and environmental impact.

- Increased Yield and Quality: By converting all gums to a hydratable form, we virtually eliminate oil losses, increasing oil yield and quality.

- Cost-Effectiveness: Our services reduce operating costs by minimizing the use of chemicals and resources, leading to a more cost-effective refining process.

- Safety and Health: By reducing the need for hazardous chemicals, we contribute to a safer working environment for your plant personnel.

Contact Us

Our enzymatic degumming services represent the forefront of bio-environmental technology in the textile industry. We are committed to providing sustainable, efficient, and cost-effective solutions that meet the highest standards of quality and environmental responsibility. By choosing our services, you are not only improving your bottom line but also contributing to a greener and more sustainable future, please contact us and confirm with our team for more information.

How to Place an Order

Reference

- Klicia A., Nadezhda Z., et al. "Enzymatic degumming: Degumming efficiency versus yield increase" European Journal of Lipid Science and Technology 2014, 23:10218.

Our products and services are for research use only and cannot be used for

any clinical purposes.

Enzymatic Degumming

Enzymatic Degumming Fig 1. Enzymatic degumming (Klicia A., 2014)

Fig 1. Enzymatic degumming (Klicia A., 2014)